Equipotential bonding in hazardous areas

Effective equipotential bonding is required for all electrical equipment installed. This also applies to systems that are located in potentially explosive atmospheres. The equipotential bonding system eliminates potential differences and thus prevents dangerous touch voltages. The potential conductor itself must not generate any ignition sparks.

We support you with solutions for permanently effective equipotential bonding.

Avoid potential differences

These can occur, for example, between the protective conductor of the low-voltage consumer system and metal water, gas and heating pipes. Therefore, all bodies of electrically conductive parts must be connected to the equipotential bonding system. These connections must be non-sparking and protected against self-loosening.

An equipotential bonding system forms the basis for safe system operation. As the system operator, you are responsible for the constant availability of the system. You must ensure that the equipotential bonding is permanently effective.

Protect your equipment and systems safely and reliably:

With equipotential bonding bars, pipe clamps and terminals that are specially designed for equipotential bonding in potentially explosive atmospheres.

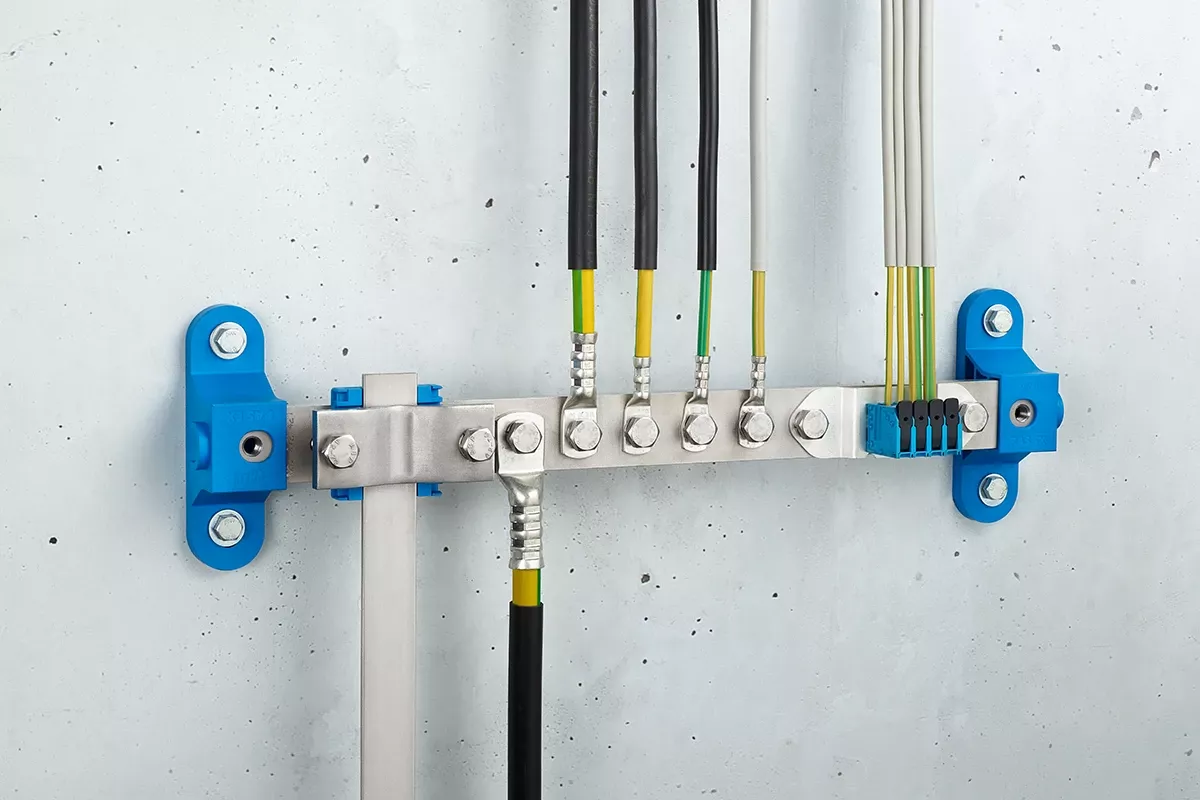

Equipotential bonding bars

The PAS EX equipotential bonding bars are non-sparking, tested with lightning currents and suitable for use in zones 1/21 and 2/22. Their non-sparking properties have been tested in a gas atmosphere, which is why they can also be used in hydrogen applications.

Cable tray systems

Conductive cable tray systems or parts of the structure alone often do not provide a safe, continuous electrical connection for equipotential bonding, which can lead to problems during conversion work. Our system solution creates a reliable ring/radially connected equipotential bonding that can be easily installed, retrofitted and maintained.

Pipe clamps (zones 1/21, 2/22)

For electrical contacting of pipes in potentially explosive atmospheres. Approved according to explosion group IIB.

Pipe clamp GSG (zone 2/22)

The Ex pipe clamp GSG has been specially developed for Ex zone 2/22. The adjustable NIRO tensioning strap offers reliable protection against self-loosening and allows flexible connection of various types of conductor.

Parallel connectors

The Cu/gal Sn parallel connector is designed for ring equipotential bonding in Ex zones (1/2 for gases IIC, 21/22 for dust), tested to be non-sparking operation and secured against self-loosening thanks to the spring ring. Without its own ignition source, it does not fall under the Ex Directive 2014/34/EU and can be used without restrictions.

Downloads

More safety in hazardous areas

Testing lightning protection systems

Protection for potentially explosive atmospheres

Safely standard-compliant

Our solutions and products are compliant with standards, among others according to EN 62305-3.

Please contact us for further information.