Railway earthing

Railway earthing and return circuits are essential to safeguard railway operations and protect people. They ensure that in the event of damage – such as a contact wire break – no dangerous voltages are transmitted to people or equipment and that the power supply is safely switched off.

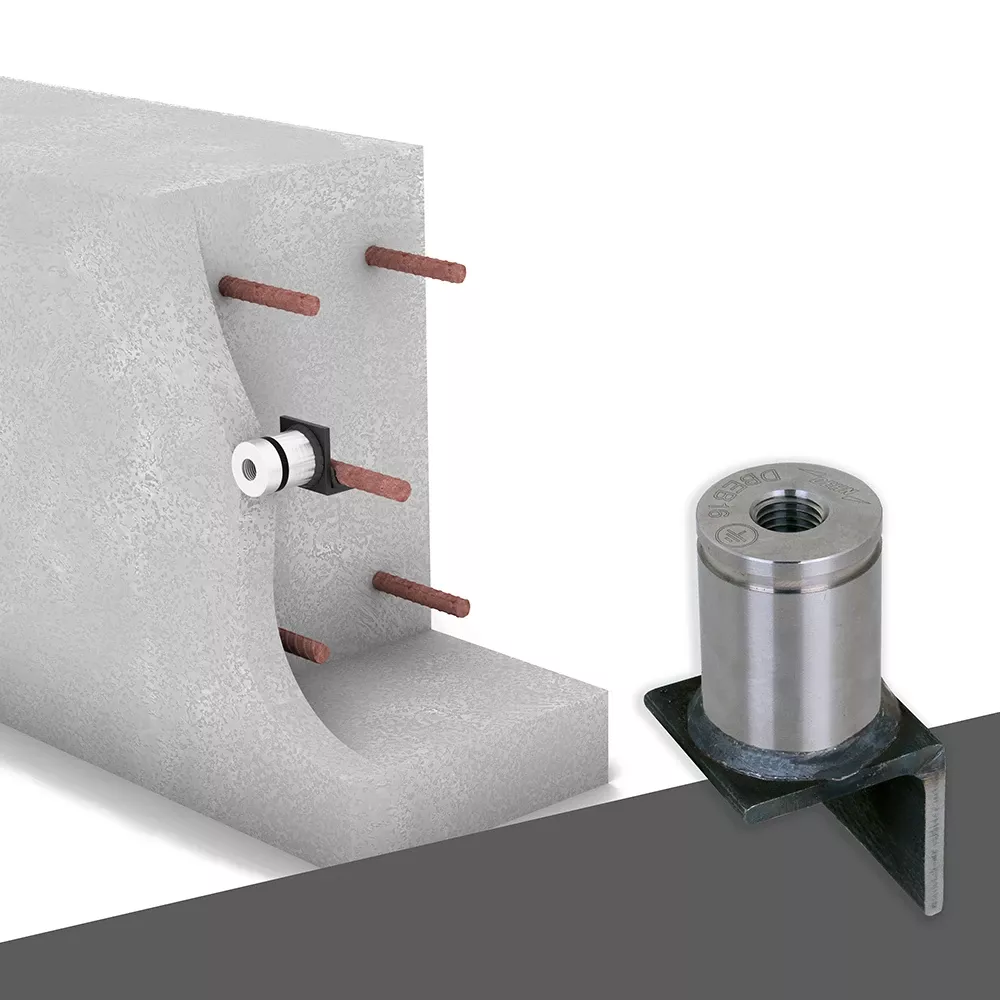

DEHN offers a complete range of earthing components from a single source: from railway earthing with earthing bridges and earthing connectors to building earthing.

Solutions for railway earthing

Railway earthing comprises the short-circuit current-proof connection of all conductive components, the return circuit and the entire earthing at the substation. These include catenary masts, tracks, steel and reinforced concrete bridges, tunnel systems, conductive components on platforms, noise barriers, boundaries and railings as well as earthing systems for power supply and telecommunications installations.

With our comprehensive range of earthing components, you can protect the infrastructure for railway operations and people in the railway environment.

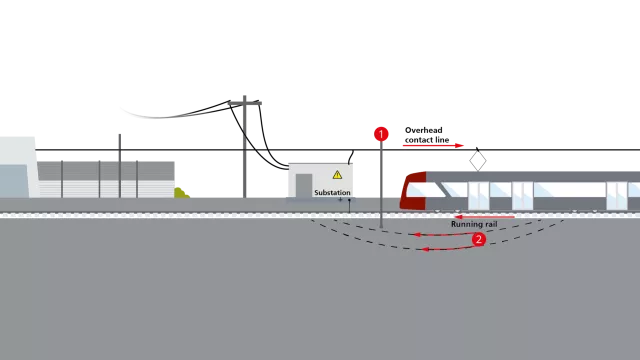

Basics of railway earthing: Railway earthing and return circuit

To protect people and systems in the event of an overhead contact line break, all electrically conductive parts must be connected directly or indirectly to the running rails. The basis for the railway earthing is the traction system earth. The running rails are the central components in this respect: they are directly connected to the surrounding ground, are therefore earthed and perform the task of returning the current. They conduct the current from the overhead contact line back to the substation. All connections between conductive system components in the break area of the overhead contact line and the running rails must be designed to withstand short-circuit currents. This means that earthing bridges and earthing connectors must be able to withstand the maximum current that occurs.

Railway earthing at a glance:

1) The operating current flows from the substation via the overhead contact line to the traction unit and supplies it with energy.

2) The current flows back to the substation via the return circuit (running rail). The running rails form the traction system earth: conductive and earthed, they are used to return the traction current (return circuit).

Short-circuit-current resistance

All connections between conductive system components and the running rails must be designed to withstand the maximum short-circuit currents.